從製作電線到樂器,銅有著廣泛的應用。聯礦以廣泛多樣的耐火材料產品支持多種銅金屬生產過程。我們專門研究銅豎爐系统和感應爐熔煉銅及銅合金,為客户提供能夠提高生產效率、設備性能、延長使用壽命的產品。

金屬銅

銅及其眾多合金以其獨特的顏色和有用的特性,成為一種廣受歡迎的多用途金屬。

粗煉與精煉

銅生產的起點,是將金屬精煉為可利用的形式。聯礦為陽極爐尤其是澆鑄勺提供耐火材料產品。

|

||

|

聯礦支持銅加工生產過程重要的第一步。

我們專注於陽極爐燒鑄勺,為内襯提供高品質耐火材料。聯礦產品耐高溫、抗磨損,優化陽極燒鑄,增强設備表現。 區域

Top Products

Floor & Sidewalls

TUFFCRETE® 28 SiC Z – high strength, silicon carbide-containing mix

Tip of Spoon

DURALAST SIC – Nitride Bonded SiC Brick

▲ 收合

|

||

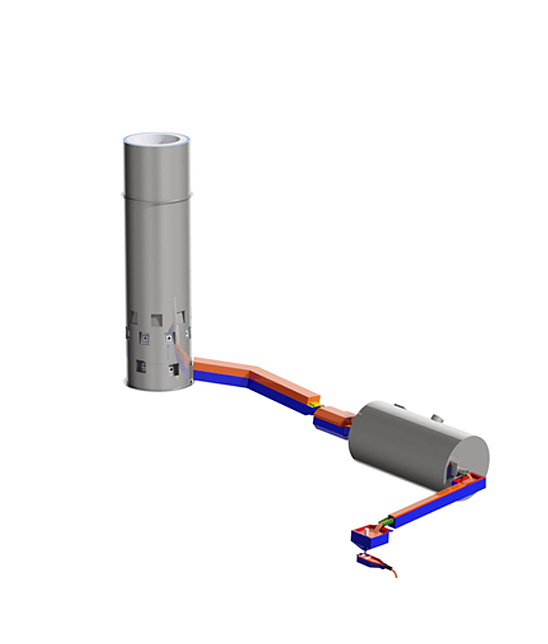

銅豎爐系統

一種被廣泛應用的銅加工方法。聯礦產品服務於這個複雜系统的所有组成部份,從豎爐到計量箱。

|

||

Copper Shaft Furnace

Impact Zone

DURALAST SIC – Nitride Bonded SiC Brick

METAL-ROK® ARMORMAX® 28 SiC Lining

DURALAST SIC – Nitride Bonded SiC Brick

MT-SC-85 SiC Mortar – Mortar for laying SiC brick. Backup Lining

CAST 2800 – Castable backup for vertical section; behind impact brick.

DRI-VIBE® 972CSF – Dry Vibratable Backup TUFFCRETE® 28 SIC Z – Backup castable for conical section; below metal line. Subhearth Support / Subhearth

TUFF-FLO 50 – LC Castable for precast Subhearth Supports and precast Subhearth.

Burner Blocks

DURALAST SIC – Precast Nitride Bonded SiC Shape

Upper Launder

Working Lining

TUFFCRETE® 80 SIC – Field cast or Precast

TUFFCRETE® 28 SIC Z – Field cast or Precast Field cast or Precast GT30CR – Field cast or Precast Field cast or Precast GT50CR – Field cast or Precast Field cast or Precast Nitride Bonded SiC Brick Spout

TUFFCRETE® 60 SiC – Precast

Slag Trap

Working Lining

TUFFCRETE® 28 SIC Z – Cast

ARMORMAX® 28 SIC – Cast GT30CR – Cast GT50CR – Cast DURALAST SIC – Nitride Bonded SiC Brick Holding Furnace

Working Lining

DURALAST SIC – Nitride Bonded SiC Brick

MT-SC-85 SiC Mortar – Mortar for laying SiC brick. Exit Spout

TUFFCRETE® 60 SIC – Precast Cylinder

LITE KASTITE 3000 – Insulating castable backup Lower Launder

Working Lining

GT30CR – High chrome if oxygen is being injected

LCF316CR – High chrome if oxygen is being injected TUFFCRETE® 80 SIC – Field cast or Precast shapes TUFFCRETE® 28 SIC Z – Field cast or Precast shapes DURALAST SIC – Nitride Bonded SiC Brick 6-Metering Box

Working Lining

TUFFCRETE® 28 SIC Z – Cast

TUFFCRETE® 60 SIC – Cast ARMORMAX® 28 SIC – Cast DURALAST SIC – Nitride Bonded SiC Brick 7-Stopper Rods & Nozzles

Stopper Rods

Hagenburger Stopper Rods – Isostatically pressed graphitized Alumina

Nozzles

TUFFCRETE® 60 SiC

8-Tundish

Working Lining

DURALAST SIC – Nitride Bonded SiC Brick

ARMORMAX® 28 SIC – Cast TUFFCRETE® 60 SIC – Cast ▲ 收合

|

||

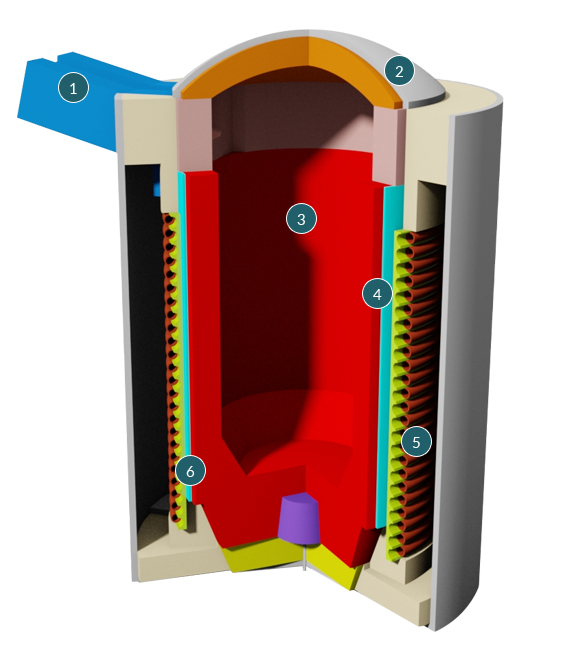

CORELESS INDUCTION FURNACE

1Spout

Matrifire® 8085ACX

79% alumina, phosphate bonded castable

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

Minro-Al® Plastic A91

87% alumina, phosphate bonded plastic

Quick-Fire® 88

88% alumina, two component phosphoric bonded castable

Precast Shapes

(alumina content 45-90%)

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Working Lining

Dri-Vibe® 291A

Mullite based dry vibratable

Dri-Vibe® 292A

Mullite based dry vibratable, less sinter depth

Dri-Vibe® 520A

90% alumina based dry vibratable

Precast Crucible/X-ACT

(alumina content 65-95%)

4Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

5Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

6Structural Component

TUFF-FLO 50A

50% alumina, low cement castable

Quick Cast® 62

95% alumina, conventional castable

Minro-Al® Cast A43

Mullite based, low cement vibration/self flow castable

Precast Shapes

(alumina content 45-90%)

▲ 收合

|