FOUNDRY

Allied has designed and manufactured monolithic refractories for the foundry industry since 1961.

Allied has designed and manufactured monolithic refractories for the foundry industry since 1961.

The foundry melt floor is a complex system of equipment that undergoes high heat and constant use. Refractories that can withstand molten metal and extreme temperatures are critical to foundry applications.

Allied has a long history of serving foundries. We provide the resources and expertise to produce and recommend the right monolithic refractory for your process. We specialize in coreless and channel induction furnaces, cupolas and ladles, and have a refractory product or precast shape to meet your specific need.

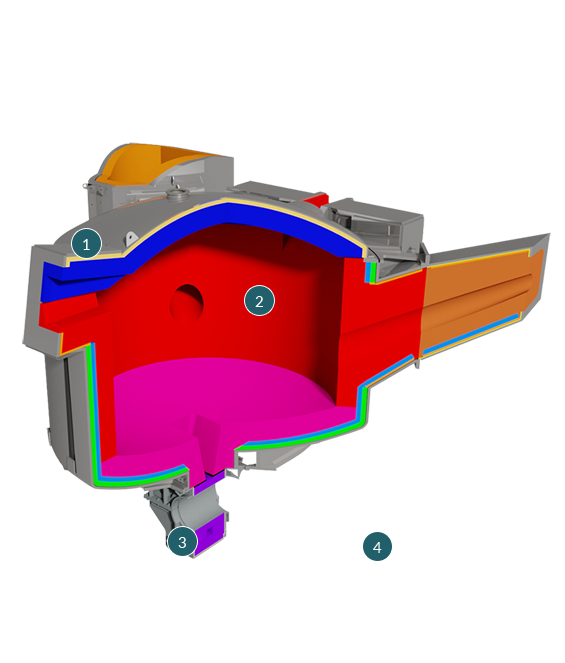

Coreless Induction Furnace

Refractory solutions for all parts of coreless induction and vacuum induction furnaces melting virtually any metal or metal alloy.

|

||

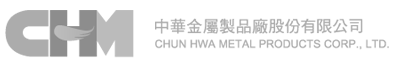

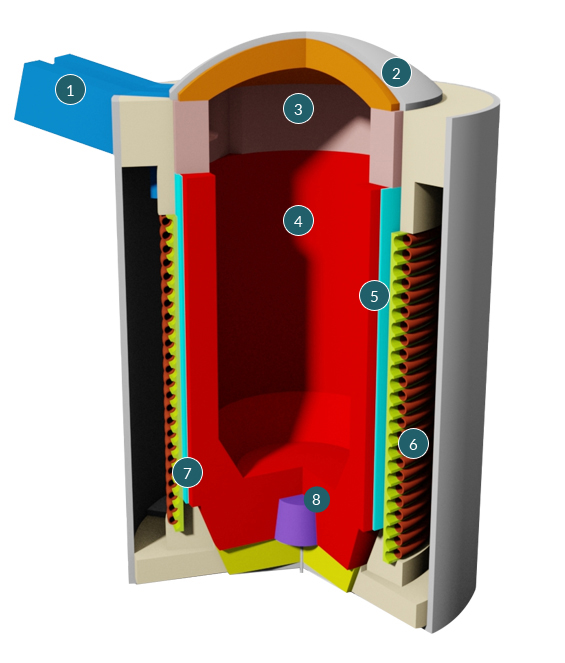

CORELESS INDUCTION FURNACE (Steel Alloy)

1Spout

Minro-Al® Plastic A91

87% alumina,phosphate bonded plastic

CW 85 HS Plastic

84% alumina,phosphate bonded plastic

Steel-Pak 90CR

High alumina,phosphate bonded plastic with chrome oxide

Precast Shapes

Alumina content 45-90%

2Cover

CW 137 CASTABLE

Bubble alumina based,insulating castable

TUFF-FLO 50A

50% alumina,low cement castable

Minro-Fire Cast F80

53% alumina,conventional castable

3Top Cap

CW 85 HS Plastic

84% alumina,phosphate bonded plastic

Dri-Vibe® 493A

High alumina dry vibratable with magnesia addition

Minro-Al® Plastic A91

87% alumina,phosphate bonded plastic

Steel-Pak 90CR

High alumina,phosphate bonded plastic with chrome oxide

4Working Lining

Dri-Vibe® 686A

84% alumina,phosphate bonded plastic

Dri-Vibe® 967CR

Used in corrosive conditions

Dri-Vibe® 975A

Low to high temp steels,irons(all furnace sizes)

Dri-Vibe® 985A

DV975A w/less sinter depth

Minro-Mag® RAM M20

Basic steels(<1mt capacity)

Minro-Mag® RAM M22 LD

Basic steels(<1mt capacity)

5Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

6Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

7Structural Component

TUFF-FLO 50A

50% alumina,low cement castable

Quick Cast® 62

Mullite based,low cement vibration/self flow castable

Minro-Al® Cast A43

95% alumina,conventional castable

Precast Shapes

(alumina content 45-90%)

8Corless Gas Purging

▲ Collapse

|

||

|

||

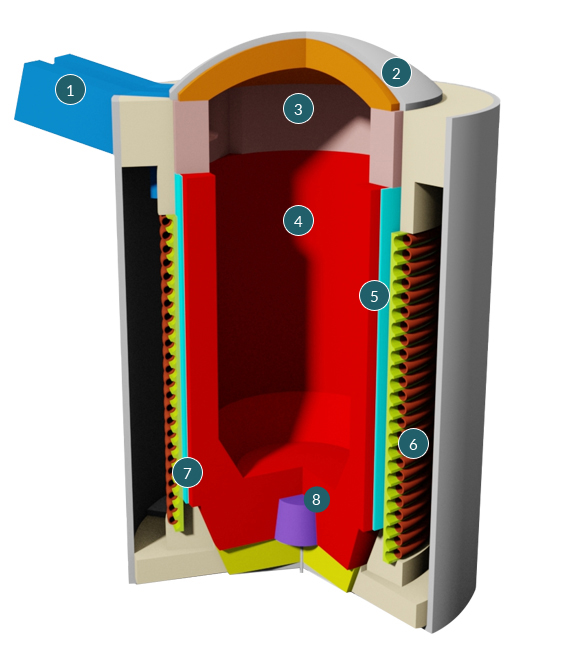

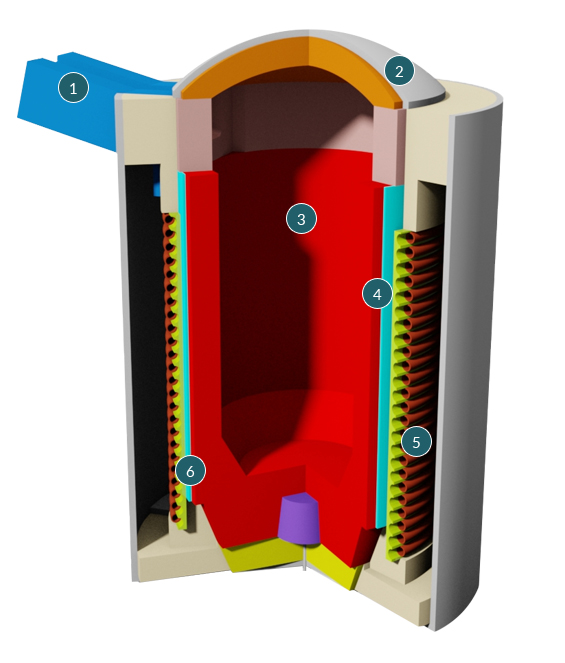

CORELESS INDUCTION FURNACE(Copper Alloy)

1Spout

CW 85 HS Plastic

84% alumina, phosphate bonded plastic

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

Precast Shapes

(alumina content 45-90%)

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Working Lining

Dri-Vibe® LGS Cu

Large grain, corrosion resistant silica dry vibratable

Dri-Vibe® 351

High alumina dry vibratable with additions of SiC and fused slica

Dri-Vibe® 497A

Andalusite based dry vibatable with addition of SiC

Dri-Vibe® 252A

Spinel bonded high alumina dry vibratable

Dri-Vibe® 355A

High alumina dry vibratable with SiC & fused silica additions

Dri-Vibe® 401Z

Silica based dry vibratable with zircon addition

Minro-Sil® 2001

Silica based dry vibratable

4Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

5Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

6Structural Component

TUFF-FLO 50A

50% alumina, low cement castable

Quick Cast® 62

Mullite based, low cement vibration/self flow castable

Minro-Al® Cast A43

95% aluminca, conventional castable

Precast Shapes

(alumina content 45-90%)

▲ Collapse

|

||

|

||

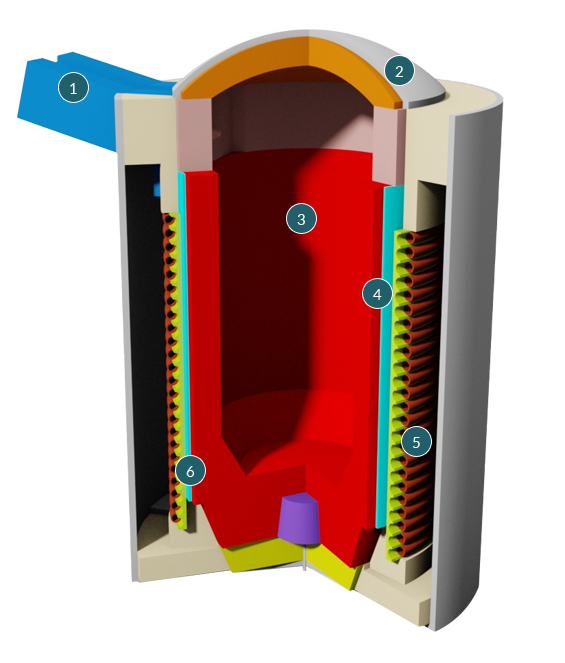

CORELESS INDUCTION FURNACE(Aluminum Alloy)

1Spout

Matrifire® 8085ACX

79% alumina, phosphate bonded castable

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

Minro-Al® Plastic A85

High alumina, phos bonded plastic

Quick-Fire® 88

88% alumina, two component phosphoric bonded castable

Precast Shapes

(alumina content 45-90%)

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating castable

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Working Lining

Dri-Vibe® 520A

90% alumina based dry vibratable

Dri-Vibe® 558A-FR

90% alumina based dry vibratable with metallic fiber addition

Dri-Vibe® 622A

90% alumina based dry vibratable, high temperature applications

Precast Crucible/X-ACT

Alumina content 45-90%

4Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

5Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

6Structural Component

TUFF-FLO 50A

50% alumina, low cement castable

Quick Cast® 62

95% alumina, conventional castable

Minro-Al® Cast A43

Mullite based, low cement vibration/ self flow castable

Precast Shapes

(alumina content 45-90%)

▲ Collapse

|

||

|

||

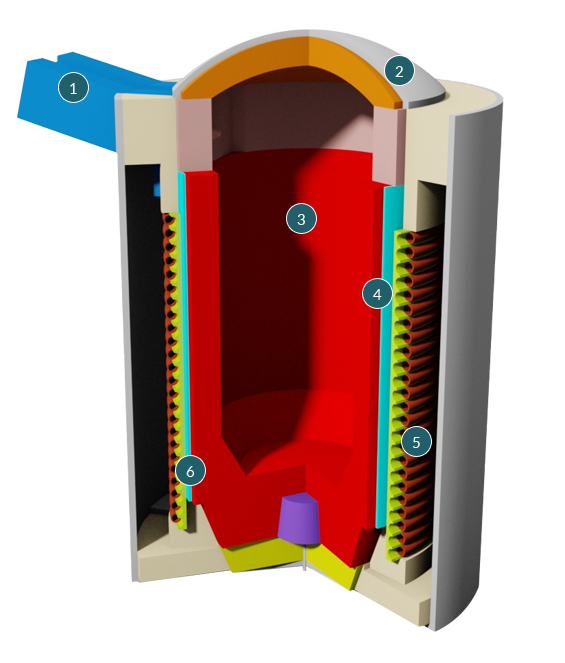

CORELESS INDUCTION FURNACE(Iron Alloy)

1Spout

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

CW Titan Plastic

73% alumina, phosphate bonded plastic

Precast Shapes

(alumina content 45-90%)

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating castable

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Top Cap

CW Titan Plastic

73% alumina, phosphate bonded plastic

Dri-Vibe® 72A

Andalusite based dry vibratable with similar expansion to silica lining

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

Dri-Vibe® 231S-XB

High strength, silica based dry vibratable with fused silica

4Working Lining

Dri-Vibe® LGS

Large grain, corrosion resistant silica dry vibratable

Dri-Vibe® LGS HTC

High temperature version of DVLGS

Dri-Vibe® 458S-Cr

Silica based dry vibratable with additions of fused silica & chrome oxide

Dri-Vibe® 462S

Silica based dry vibratable with addition of fused silica

Dri-Vibe® 799A

Andalusite based dry vibratable for resistance to chemical erosion

Minro-Sil® RAM 1001

silica based dry vibratable

Minro-Sil® 2001

silica based dry vibratable

5Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

6Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

7Structural Component

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Al® Cast A43

95% aluminca, conventional castable

Quick Cast® 62

Mullite based, low cement vibration/ self flow castable

Precast Shapes

(alumina content 45-90%)

8Corless Gas Purging

▲ Collapse

|

||

|

||

CORELESS INDUCTION FURNACE(Zinc Alloy)

1Spout

Matrifire® 8085ACX

79% alumina, phosphate bonded castable

Minro-Al® Plastic A76

67% alumina, phosphate bonded plastic

Minro-Al® Plastic A91

87% alumina, phosphate bonded plastic

Quick-Fire® 88

88% alumina, two component phosphoric bonded castable

Precast Shapes

(alumina content 45-90%)

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Working Lining

Dri-Vibe® 291A

Mullite based dry vibratable

Dri-Vibe® 292A

Mullite based dry vibratable, less sinter depth

Dri-Vibe® 520A

90% alumina based dry vibratable

Precast Crucible/X-ACT

(alumina content 65-95%)

4Slip Plane & Relataed Materials

Vaporshield

Mica with exceptional resistance to metallic vapor and salt penetration

CM30 SRP (Micacombi)

Mica backed by 3mm ceramic paper

GM 40SRP Mica

Mica laminated with woven glass fabric

5Grout

Grout 163ACF

Tabular alumina troweling mix with ceramic fibers

Grout 563A

Fused alumina troweling mix with red pigment

Grout 663A

Fused alumina troweling mix

Minro-Al® Cast A44

Tabular alumina vibration castable

Coil Cast 97A

Tabular alumina self leveling castable

Minro-Sil® Grout S15

Silica based troweling mix

6Structural Component

TUFF-FLO 50A

50% alumina, low cement castable

Quick Cast® 62

95% alumina, conventional castable

Minro-Al® Cast A43

Mullite based, low cement vibration/self flow castable

Precast Shapes

(alumina content 45-90%)

▲ Collapse

|

||

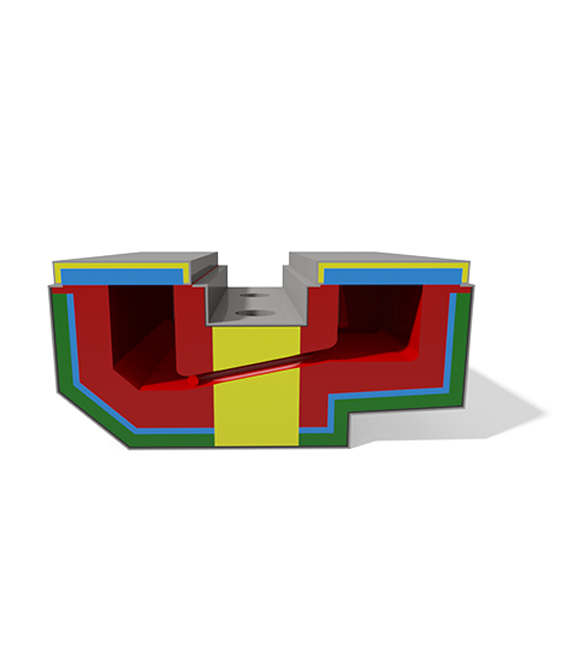

Channel Induction Furnace

Refractory solutions for melting, holding and pouring iron, copper, aluminum and zinc alloys. Our trusted product lines: V-CAST®, DRI-VIBE® and MINRO-AL.

|

||

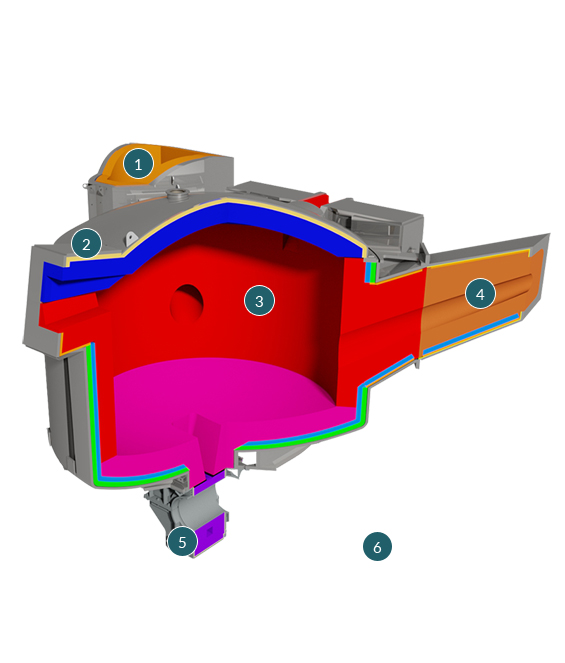

Channel Induction Furnace(Iron)

1Receiver/Pour Spout

CW 965 Castable

Mullite based low cement castable

Minro-Al® RAM A29

High alumina dry vibratable with SiC

Dri-Vibe® 336Cr

High alumina dry vibratable with chrome

V-Cast® 712A

High alumina, low porosity castable with addition of SiC

2Cover

CW 137 CASTABLE

Bubble alumina based, insulating castable

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

3Working Lining

Dri-Rok® 2029

Large grain, high alumina dry vibratable with SiC

Dri-Rok® 2036 Cr

Large grain high alumina dry vibratable with chrome

Dri-Vibe® 336Cr

High alumina dry vibratable with chrome

Minro-Al® RAM A29

High alumina dry vibratable with SiC

V-Cast® 426A

High alumina, low cement castable with SiC

V-Cast® 707A

High alumina, low porosity castable with SiC

V-Cast® 712A

High alumina, low porosity castable with 12%SiC

4Receiver/Pour Spout

CW 965 Castable

Mullite based low cement castable

Minro-Al® RAM A29

High alumina dry vibratable with SiC

Dri-Vibe® 336Cr

High alumina dry vibratable with chrome

V-Cast® 712A

High alumina, low porosity castable with addition of SiC

5Inductor

Dri-Vibe® 306A

Alumina based spinel forming dry vibratable

Dri-Vibe® 331A

High alumina dry vibratable with 30% MgO

Minro-Mag® Ram M10

Magnesia based dry vibratable

Minro-Mag® Patch Ram M11

Magnesia based inductor capping castable

Patch 457A

Alumina based inductor capping castable

Dri-Vibe® 696M

Magnesia based spinel forming dry vibratable

6Gunning/Repairs

CW Duragun 90 NF

90% alumina gunning refractory

MATRIGUN 70AC-HOT

67% alumina gunning refractory

TEK-GUN 31A

High alumina, hot gunning mix

▲ Collapse

|

||

|

||

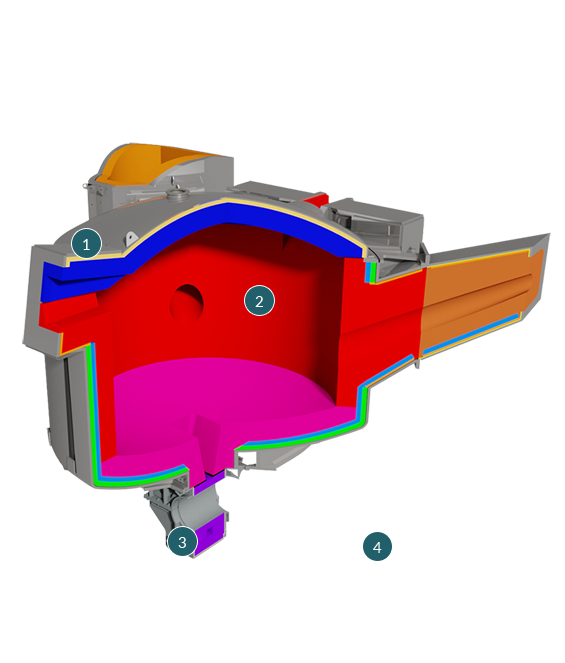

Channel Induction Furnace(Copper)

1Cover

Minro-Fire Cast F80

53% alumina, conventional castable

CW 137 CASTABLE

Bubble alumina based, insulating castable

TUFF-FLO 50A

50% alumina, low cement castable

2Working Lining

LCF 798A

Andalusite based, low cement castable

Minro-Al® RAM A29

High alumina dry vibratable with SiC

TUFF-FLO 608

Mullite-based castable with SiC addition

V-Cast® 426A

High alumina castable with SiC

V-Cast® 707A

Low porosity, high alumina castable with SiC

3Inductor

Dri-Vibe® 252A

Spinel bonded high alumina dry vibratable

Dri-Vibe® 351A

High alumina dry vibratable with SiC & fused silica additions

Dri-Vibe® 355A

High alumina dry vibratable with SiC & fused silica additions

Dri-Vibe® 357A

High alumina dry vibratable

Dri-Vibe® 432Cu

Silica based dry vibratable

V-Cast® 426A

High alumina castable with silicon carbide

Minro-Al® Ram A34W

High alumina wet ramming mix with SiC

Minro-Sil® RAM 1001

Silica based dry vibratable

Minro-Sil® 2001

Silica based dry vibratable

4Gunning/Repairs

CW Duragun 90 NF

90% alumina gunning refractory

MATRIGUN 70AC-HOT

67% alumina gunning refractory

▲ Collapse

|

||

|

||

Channel Induction Furnace(Zinc)

1Cover

CW 137 CASTABLE

Bubble alumina based, insulating castable

TUFF-FLO 50A

50% alumina, low cement castable

Minro-Fire Cast F80

53% alumina, conventional castable

2Working Lining

Matriflo Zn

Mullite based low cement castable, thermally stable

Matripump 80AC

Bauxite based low cement castable

Quick Cast® 52AC

51% alumina low cement castable

Quick Cast® 62AC

Mullite based, low cement vibration/self flow castable

Precast shapes

60-90% alumina based

Super Duty Firebrick

Super duty dry press firebrick

3Inductor

Dri-Vibe® 558A-FR

90% alumina based dry vibratable with metallic fiber addition

Dri-Vibe® 594-FR

Andalusite based dry vibratable with metallic fiber addition

Dri-Vibe® 595A-FR

Mullite based dry vibratable with metallic fiber addition

Matrifire® 8085ACX

79% alumina, phosphate bonded castable for capping

4Gunning/Repairs

CW 85 HS SEAL

85% alumina, phosphoric bonded patching material

MATRIGUN 70AC-HOT

67% alumina gunning refractory

Steel-Pak 90 Cr

High alumina, phosphate bonded plastic with chrome oxide

▲ Collapse

|

||

Pressurized Casting Furnace

Refractory solutions for melting, holding and pouring iron, copper, aluminum and zinc alloys. Our trusted product lines: V-CAST®, DRI-VIBE® and MINRO-AL.

|

||

Pressurized Casting Furnace

1Working Lining

LCF 579A

LCF 596CR

MINRO-AL® RAM A29

TUFFCRETE® 608

V-CAST® 426A

V-CAST® 707A

2Spouts

Castables

plastics/plasters (available in phosphate bonded alumina compositions)

Precast shapes

3Inductor

DRI-VIBE® 252A

DRI-VIBE® 351A

DRI-VIBE® 355A

DRI-VIBE® 357A

DRI-VIBE® 432 Cu

MINRO-AL® RAM A34W

V-CAST® 426A

4Cover

CAST 299A

LCF 52A

MINRO-FIRE® CAST F80

5Related materials

MINRO STIR PRO NOZZLES (Diffuser / Plug)

Board, Brick and other Ancillary Materials

Thermocouples

Vibrators and Installation Equipment

Patented (EVS) Electric Vibration System

▲ Collapse

|

||

Pressure Pour Furnace

Leading dry vibratables, castables, plastics and precast shapes for all pressure pour furnace areas. A wide selection of repair/maintenance and installation products supplements our refractory offerings.

|

||

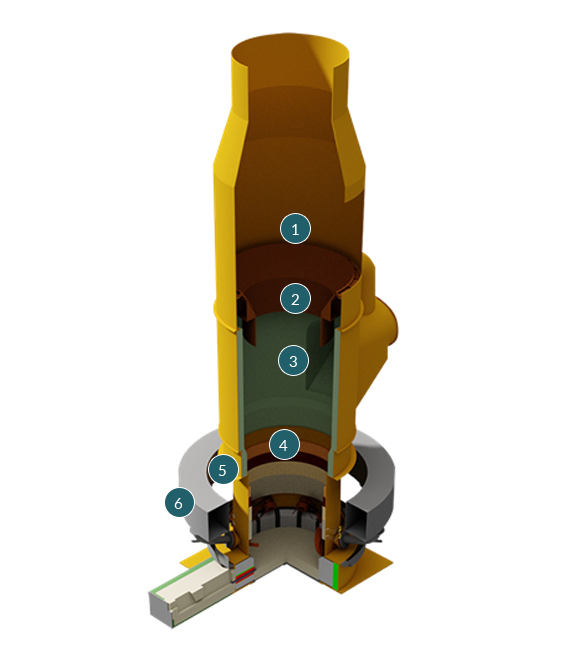

Cupola

Allied has refractory products and expertise to serve and optimize cupolas of any size melting a wide range of foundry alloys.

|

||

Cupola

1Charge Ring

Metal-Rok Shapes

High metallic fiber loaded precast shape

2Upper Stack

Stackcrete 62M

Mullite based low cement, abrasion resistant castable

Guncast® 26 LI

45% alumina abrasion resistant gun mix

Stackcrete® 608

Mullite based low cement, abrasion resistant castable with SiC

3Meltzone

DURALAST

High conductivity brick

Stackcrete® G

High conductivity, carbon based shotcrete mix

Stack Gun 85 SiC

85% SiC, low clay gunning mix

CW GUN 519

44% SiC gunning mix

CW GUN 518

44% SiC gunning mix

CW GUN 516

44% SiC gunning mix

DURAMELTZ® Technology

Reduces rate of refractory wear

4Well

CW 379 PLASTIC GT

Resin bonded high alumina graphitic silicon carbide plastic

CW GUN 519

44% SiC gunning mix

CW GUN 518

44% SiC gunning mix

CW GUN 516

44% SiC gunning mix

V-Cast® 980A

High alumina low cement castable with SiC+C

DURAMELTZ® Technology

Reduces rate of refractory wear

5Taphole

CW 379 PLASTIC GT

Resin bonded high alumina plastic with addition of SiIC +C

Omega Plastic

Resin bonded high alumina plastic with SiC+C

Precast Shapes

High alumina with SiC+C

V-Cast® 133A

High alumina low cement castable with SiC+C

DURAMELTZ® Technology

Reduces rate of refractory wear

6Separator

CW 137 CASTABLE

90% alumina gunning refractory

CW 469 RAM

Resin bonded high alumina graphitic silicon carbide ramming mix

Omega Ram

Resin bonded high alumina ramming mix with SiC+C

DURAMELTZ® Technology

Reduces rate of refractory wear

▲ Collapse

|

||